Understanding EN Regulations

European Standards (ENs) are documents that have been ratified by one of the three European Standardisation Organisations ESOs, CEN, CENELEC or ETSI; recognised as competent in voluntary technical standardisation, EU Regulation 1025/2012.

European Standards (EN)

"carries with it the obligation to be implemented at national level by being given the status of a national standard and by withdrawal of any conflicting national standard".

European Standards automatically become national standards in each of the 34 CEN-CENELEC member countries. What this means is when an EN standard is approved (harmonised) the local standard must be withdrawn.

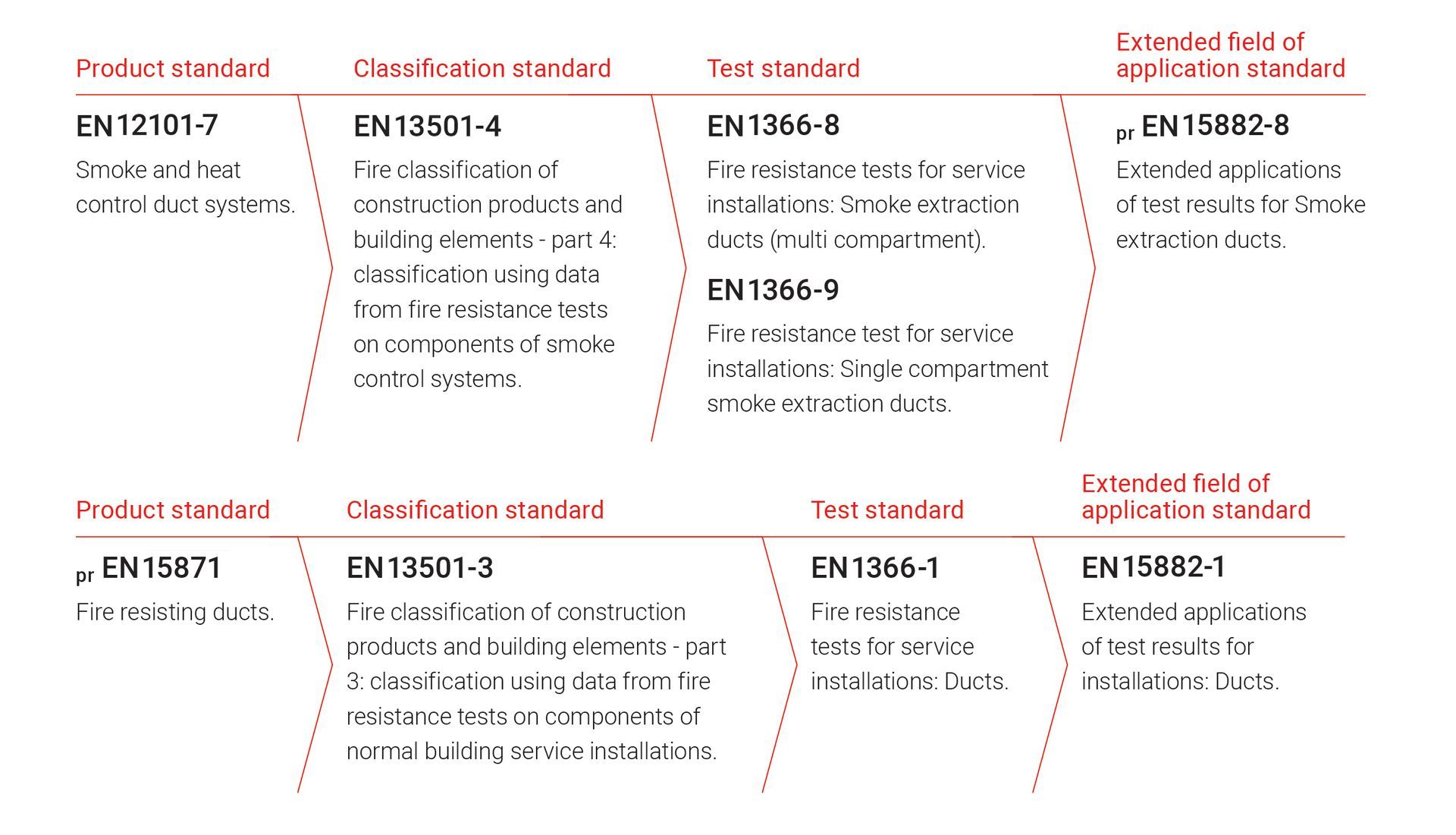

Ductwork is split between smoke control ducts and fire resisting ducts.

Smoke Control Ducts are subject to an EN standard. Since July 2013 all smoke extract systems must comply with the standard EN12101-7, and be classified to EN standard 13501-4. The test standards are, multi-compartment EN1366-8 and single-compartment EN1366-9. In keeping with the requirements of the Construction Products Directive, Regulation 305, all smoke extract ducts must carry the CE symbol, or in the UK, the UKCA symbol. Factory production control must be in place with the manufacturer, and a manufacturer must demonstrate this.

Smoke Control Ducts are ventilation ducts used to exhaust smoke or heat during a fire. Make up air systems are also considered part of the smoke control system. Smoke Control Ducts in multi-compartment applications must prevent flashover from occurring.

The test standard EN1366-8 states

“the test shall be made on a test specimen representative of the complete duct assembly, including integral or intended insulation on which information is required in”.

Thor Duct® is a complete system suitable for smoke and heat extraction, classified EN13501-4 having been tested with Insulation, in accordance with the standard EN1366-8 for 30, 60, 90 and 120 minute protection E (Integrity) and I (Insulation). Single compartment EN1366-9 is also classified and available. With Thor Duct® you know you have every requirement covered. The maximum size multi-compartment smoke extract duct permitted is 1250x1000mm, 1000 Ø. The maximum size single compartment available from Thor Duct® is 2000x2000mm.

Fire resisting ducts, other than smoke applications, are subject to the test standard EN1366-1, which became national standard in April 2015. The classification report for fire ducts is EN13501-3. A harmonised standard is still being ratified, and until such time as it is adopted, fire ducts with the exception of smoke ducts, do not require a CE marking.

Thor Duct® is a complete fire resisting system, classified EN13501-3 having been tested with Insulation, in accordance with the standard EN1366-1 for 30, 60, 90 and 120 minute protection E (Integrity) and I (Insulation). The maximum size fire resisting duct permitted is 2500x1250mm, 1000 Ø. With

Thor Duct® you know you have every requirement covered.

Would you like to get a copy of our brochure, Understanding the new EN regulations?

Fire tests are conducted with

✓ Mechanical and dynamic pressure

✓ Leakage measurements

✓

Cross sectional area movements

✓ Different orientations

✓ EN 1363-1 fire curve

✓

Fire types A and B and C