Typically, we work to a maximum of 1250x1000mm, and 1000 Ø. This is not an absolute.

In order to determine the maximum size permitted on the market as a certified product, the test standards are the critical document. The test standards are EN1366-1 and EN1366-8 and EN1366-9. The standards contain the test sizes which a manufacturer is required to submit for testing as evidence of the duct’s performance. There are two different tests for EN1366-1, a type A and a type B. Both have different duct sizes for testing.

Under EN1366-1, we submit for Type A testing a duct measuring 1000x500mm. For a Type B test, the size is 1000x250mm. There are specifications contained in the standard for the length of ducts, inside and outside the furnace, the location of access doors, the flow rates and the pressure during tests.

In Table 7 of the test standard EN1366-1, the sizes can be increased as follows.

Sizes of Ducts

A test result obtained for the standard sizes of duct A and duct B specified in tables 1 and 2 is applicable to all dimensions up to the size tested together with the increases given in the table below.

| Rectangular width mm | Rectangular height mm | Circular diameter mm | |

|---|---|---|---|

| Duct A | +250 | +500 | +200 |

| Duct B | +250 | +750 | +370 |

It is not possible to offer larger ducts under the test standard. The sizes are dimension specific and not area, in other words, we cannot offer 1400 X 400 within the understanding of an area calculation of 1250x1000mm.

A similar guidance is provided for round construction, allowing for an increase from the test specimen size to 1000 Ø.

What do I do if I need a different size that falls outside the scope of EN1366-1?

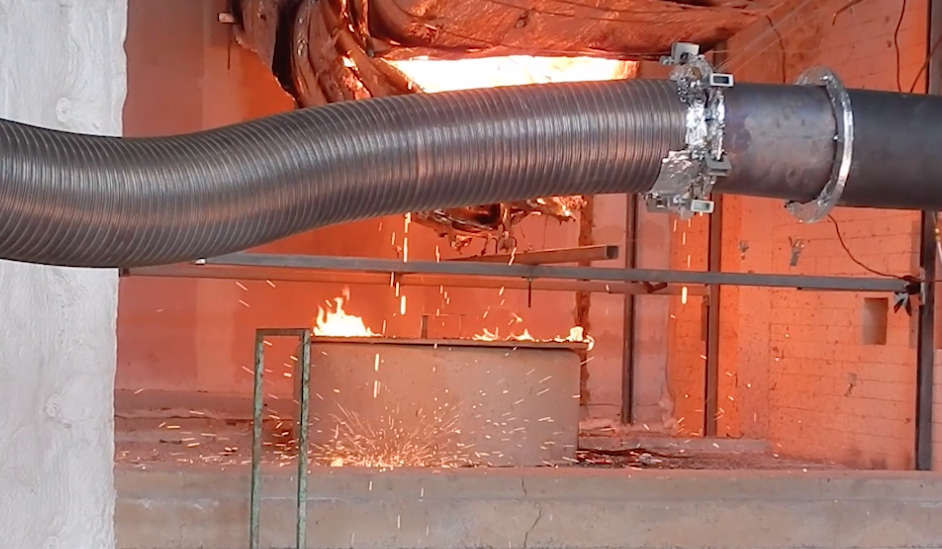

Thankfully we have an extended field of application EN15882-1. In this document, we are given clarification that covers changes in materials, thicknesses, pressures, uses and sizes. The document permits us to provide a certified product up to a maximum of 2500x1250mm. This greatly enhances the options for customers. To achieve certification, the standard EN15882-1 requires a manufacturer to provide test evidence as to the performance of the ducts, submitting their maximum size for evidential testing. That means testing 2500x1250mm, both type A and type B, vertically and horizontally.

To achieve an acceptable result for the market, the construction will often be different, due to the stresses a hydrocarbon fire will create on surface areas of 2500x1250mm. Conducting such tests are often limited to a small number of very large furnaces in Europe, who have the experience of doing such large tests and conducting them safely.

Thor Duct ®

has submitted a 2500x1250mm duct to the necessary vertical and horizontal tests and achieved an EI rating of 90 minutes. This gives our clients the advantage of being able to size ducts within the range 1250x1000mm – 2500x1250mm. One side may extend to 2500mm, however the other side must not exceed 1250mm. The sizes are not an area calculation, i.e. 3000x500mm is not possible as a single duct.

Thor Duct XL

To specify a size greater than the standard 1250x1000mm, your specification should refer to Thor Duct XL. This will ensure that your client receives the correct product, and not an accidental size without appropriate testing. Always request access to the classification report to the standard EN13501-3, which will validate the performance of the ductwork selected.

For smoke applications, the standard EN15882-8 has not be harmonised. The reason is that EN1366-8 tests are for smoke leakage, and the test measures oxygen levels at differing points of the test. This has been formulated for the standard 1000x250mm test, but not for larger sizes. At this point in time, smoke ducts are not available above 1250x1000mm. The evidence from the extended field standard EN15882-1 may be a basis for a qualified person to make a considered view.

The construction methods, and the hanging considerations, demonstrated in the tests must be replicated when being installed on site, to offer a compliant solution. A full install manual is available to trained installers from thorduct.com.

Looking to Specify?

All Thor Duct ® products are fully tested and compliant across all international codes.