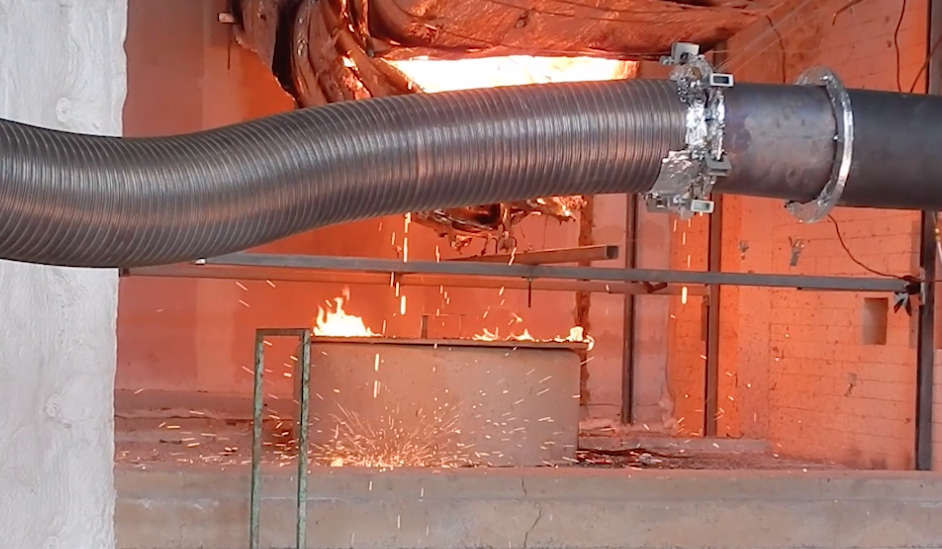

The practice of using fire tested insulation on ventilation ducts is common throughout the world. A fire risk is observed, and insulation is used to provide the protection.

The performance of the insulation in a fire scenario is dependent, not only on its own properties, but any other building element it is in contact with.

This is particularly true of ducts. The insulation is fixed to the ductwork, and depends on the ductwork maintaining its integrity during a fire event. Should the ductwork loose its integrity, the insulation moves and the insulation properties are lost. The initial assessment to use Insulation, while a correct one, ignores the importance of a proven (E) Integrity classification for the ductwork. Testing of both ducts for integrity (E), and with (I) insulation, providing combined evidence is the way forward.

Smoke Extract ducts tested to EN1388-8 and classified 13501-4 take their Insulation performance from combined duct and insulation tests under EN1366-1.

No guess work, no hoping, it’s evidential.

Need To Know More?

Contact us today to find more about training and CPD from Thor Duct®.